The Wise Anodize

Anodizing is one of the processes that is used to give metal a stylish finish. This technique uses acid to create a hardened and corrosion resistant layer that is integrated in to the metal. It is unmatched by any other process.

An electrochemical process changes that crystal structure near the surface of the aluminum alloy and allows for it to be dyed. Making it unable to chip or peel. Which means it is completely different from paint, wraps or plating. Ad the volume of oxide produced by the process is greater than the metal it is replacing, meaning the coating is about thirty percent thicker.

The process of anodizing is six-steps that leaves you with metal that has an amazing finish. First, the item must be cleaned. Acid cleaners are normally used because they remove grease and dirt easier. Second is the pre-treatment. Etching for a matter style look and brightening or bright dip for a shinier, mirror like look. Step three is where the anodizing is done. An anodic film is built and combined with the metal by passing through an acid electrolyte bath. This can be achieve one of two ways, batch or coil. Batch is when the material is fully immersed into a series of treatment tanks. Coil is when the metal is in a continuously unwinding pre-rolled coil. These pass through a series of anodizing, etching and cleaning tanks, then they rewind for the shipment and fabrication process. The fourth step is where the color is added by one of four processes. Electrolyte, integral, interference coloring or organic dyeing. After the coloring is complete the material is sealed. The anodic film is them secured within the metal giving the surface a resistance to staining, corrosion and abrasions. Then it is all finished with a quality control check. Making sure everything looks as it should and is in pristine condition.

Anodizing is considered environmentally safe, non-toxic and is not harmful to human health. Very durable. A portion of the material used to build the Willis Tower in Chicago was anodized to add strength. Also satellites have been anodized to help them withstand outer space. It has color stability, won't fade from the sun. Very easy to maintain, rinsing with water will normally do the job or using a small amount of soap with water, or you can use a mild abrasive cleaner for more difficult deposits. Its aesthetics are unlike any others, with the anodizing process the metal keeps its metallic appearance.

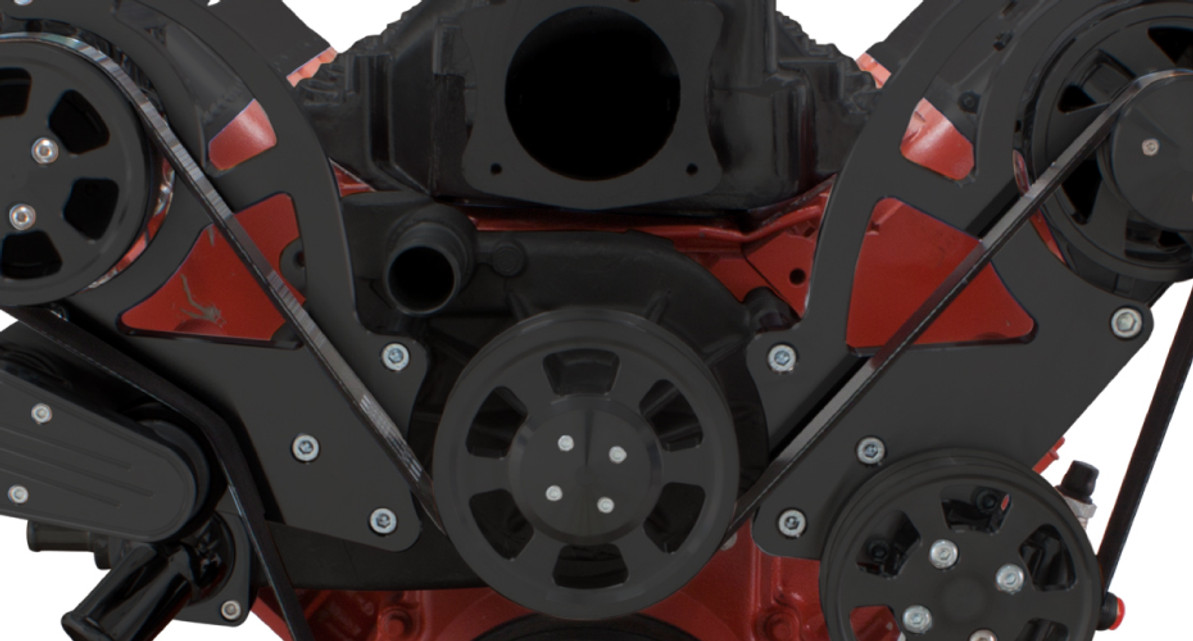

We choose to use the anodizing process on our products because of everything that was previously stated. CVF products are anodized using the bright dip treatment. The finish truly has shine to it and will definitely give your engine a little something extra.

If you would like to know more about the anodizing process check this page out:

http://www.anodizing.org/?page=what_is_anodizing

Recent Posts

-

Chevy LS Intake Manifold Clearance Issues: How to Fix Them

Swapping in a large performance intake manifold — like the Fast 102mm — on a Chevy LS engine is a po …Mar 3rd 2026 -

What is VVT and Do I Have It? (Chevy LS Guide)

If you're building or swapping a Chevy LS engine, one of the first things you need to determine is w …Feb 25th 2026 -

Hot Rod Bio: 1,500 Horsepower on pump gas - Anthony’s ProCharged 1970 Chevelle

At SEMA 2025 we caught up with Anthony and his 1970 Chevelle that makes a very casual 1,500 horsepo …Jan 23rd 2026